The Orsat AutoGC System

Fully automated, round-the-clock, ambient air VOC monitoring

The Orsat AutoGC System has been developed to enhance the analysis of VOC ozone precursors. The system is based on a laboratory quality analytical system using cryogen-free concentration and gas chromatography. Composed of a custom integration of the Markes UNITY-xr Thermal Desorber and an Agilent 7890B Gas Chromatograph with the OpenLab EZChrom CDS, the Orsat AutoGC software and hardware is designed to automate many of the day-to-day site activities, freeing valuable staff resources for system evaluation and data validation.

Orsat’s software creates unique file names for each hourly data file and initiates automatic collection of routine quality control samples necessary to monitor the system performance. Utilizing these easily identifiable file names to automate data archiving and file transfer allows the system to operate with minimal intervention freeing up operator time for data evaluation. It also reduces the time needed to locate specific files and reduce potential data losses. Additionally we optimize the system environment to provide the structure necessary for the automated environment. All installation, configuration, final testing and third party software products integral to the automation process are included.

Custom Site Configuration

Orsat’s custom site configuration is designed to automate several aspects of operations on the AutoGC System. In reality, it is a combination several packages. The goal is to relieve the operator of repetitive tasks required to maintain the system on a daily basis.

Custom site configuration includes:

• VOC Analyzer • Merlin MicroScience Dilution (MMSD-MPV) System • Electronic Logbooks • Remote Access Configuration • Customized Chromatographic Data System • Method Files • Merlin EZ Sequence • Merlin AutoGC Xplorer (MAX) Cloud Services (optional) • Standard Operating Procedures

Hardware

The Orsat AutoGC is composed of a VOC analyzer and the humidified blank/calibration system.

VOC Analyzer

The foundation of the AutoGC is one of two VOC analyzer systems: the PerkinElmer (PE) Continuous VOC Analyzer System or an Agilent 7890B GC with Markes UNITY-xr thermal desorber.

Agilent GC with Markes UNITY-xr Thermal Desorber

The custom integration The UNITY-xr Air Server allows continuous, unattended and cryogen-free monitoring at low to sub-ppb levels and automatic sequencing between a minimum of 3 channels (sample, standard & blank). Markes Series 2 TD systems offer splitless desorption & uniquely high cryogen-free retention volumes for ultra-volatiles such as acetylene & ethane. Systems are operated in remote, unattended monitoring stations, with data accessed via telemetry and processed/validated at remote network control centres.

Humidified Blank/Calibration System - The Merlin MicroScience VOC Dilution System

The Merlin MicroScience VOC Dilution System.

This gas dilution system is a major enhancement to the automated VOC analyzer. It includes hardware to generate humidified air utilizing air from the existing air purifier and compressor. This humidified air is used to generate daily system blanks and the calibration standard diluted for introduction into the Markes UNITY-xr Thermal Desorption (TD) system. Calibration samples are generated by dilution of static span gases of 30 ppbv to 10 ppmv concentrations with humidified air using low-flow fixed orifices. This dilution system is capable of dilution ratios of as much as 1:10,000. It is a low volume dilution apparatus with a clearing time of less than five minutes and all wetted parts are constructed of stainless steel.

The system has been modified in several ways to incorporate it into the VOC analyzer. By adding electrically actuated solenoid valves we can control the delivery of blanks and check samples via the EZChrom data system (using timed events). This dilution system reduces errors in long term evaluation of the system performance by allowing the use of a single 33 L canister of a standard at 1 ppmv concentration, which can provide daily calibration checks for periods of up to several months. Using higher pressure cylinders could allow the use of the same standard over the entire season, thus reducing the variability of canister cleaning and refill errors. Additionally, standards used contain only 14 components used as reference peaks for retention time stability as well as propane and benzene used for calculation of system recoveries. At the 100 ppbv to 1 ppmv level these standards are less expensive, more stable and often more accurate than those provided at ppb levels.

A Few Specifics:

Input Pressures (standard): 3–100 psig (0.2–7.0 kg/cm2); Other ranges optional

Output Pressure (standard): 0.5–3.0 psig (0.04–0.2 kg/cm2); Other ranges optional

Output Flow (standard): 25 ml/min minimum; Flows to 500 ml/min optional

Construction: 100% type 316L stainless steel tubing in blend path

Power Input: 110 VAC

Mounting: Pedestal or rack

Stability: Restrictors: ± 2% of reading / year

Repeatability: Restrictors: ± 1% of reading

Software

Customized software from Merlin MicroScience integrates seamlessly with the manufacturer’s data systems to provide the AutoGC with the structure necessary for automated tasks including sequencing and archiving.

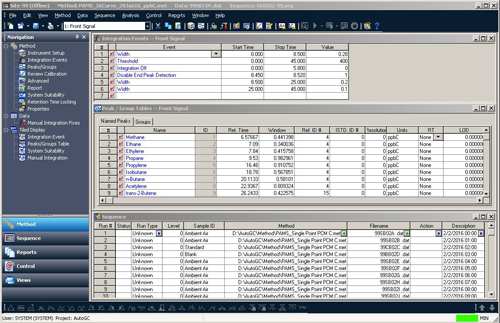

The Chromatographic Data System

The workhorse of each AutoGC is its chromatographic data system (CDS). The CDS collects and analyzes the results from the gas chromatograph outputting ASCII data files. The collection of data is managed by method files and sequence files. The AutoGC includes method files for ambient samples, blanks, calibration checks, and retention time checks. Sequence files automate the AutoGC by scheduling sequences of analyses.

Method Files

Method files contain the specific analysis instructions such as compound names, retention times, retention windows, and calibration information for each compound. The method also specifies hardware settings such as oven temperature profiles, flame ionization detector temperatures, and flow rates. Each system will use pre-set methods for ambient samples, blanks, calibration checks, and retention time checks daily.

These methods require optimization to improve separation of the compounds being analyzed. In addition, the data output must conform to the needs of the the automation systems.

The EZChrom Method Editor.

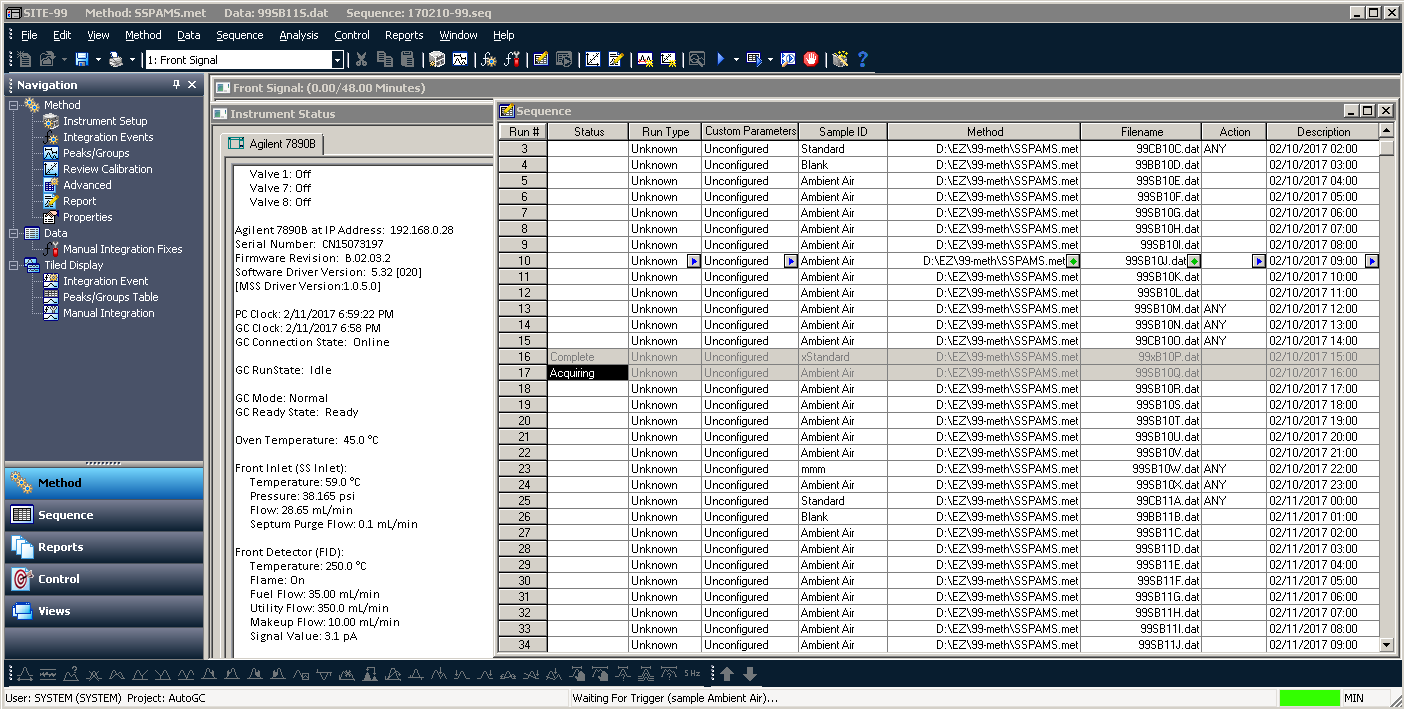

Merlin EZ Sequence

The Merlin EZ Sequence software generates text files that can be imported into the data system sequence builder. Sequence files are the instruction set for the gas chromatography data system. They control sampling and specify the method to be used for each sample. The sequence also assigns all hourly data unique file names. The Sequence software allows the operator to configure sampling for weeks, generating not only unique hourly file names but also scheduling blanks, calibration checks, retention time checks and daily archiving of data.

Unique file names are of particular importance on a continuous analyzer. In a single month of operation the system can generate over 740 raw data files. The naming scheme for data files includes the site designation, column, sample type (i.e. sample, calibration, blank), and month, day and hour of the day specification. This allows files to be sorted using conventional file handling strategies and to group the files based on some degree of knowledge of their contents. More significantly, by generating these files using a software routine we relieve the operator from tedious typing chores, reduce the potential for errors and free up valuable time.

The EZChrom Sequence Editor.

Merlin EZSequence setup dialog.

Sequences control the introduction of routine quality control samples via activation of a visual basic (VB) program which controls valve relays. By inserting the VB program into the sequence, quality control samples are scheduled automatically or the operator can add them into a running sequence. Additional hardware is included to allow the introduction of statically-diluted, second-source checks and retention time checks. The sequence generator automatically schedules daily calibration checks and blanks as well as weekly second-source check standards and retention time checks.

When building a sequence, blanks, and calibration checks are scheduled daily and the operator can choose to have these samples automatically run in the first four hours of each day. Under these conditions the blank and calibration runs occur on hours 00 and 01 or at hours 02 and 03 every other day, thus reducing losses of data for these hours to equal halves. Alternatively, these blanks and calibration checks can be scheduled to occur on a rotational basis throughout the day and night across the monitoring season. This further reduces the loss of data for any given hour to a minimum.

Electronic Logbooks

Site logbooks used to record daily activities at field sites.

Using standard Windows features an electronic logbook can be configured for each site data acquisition computer. The logbook is crucial to efficient operation and validation of daily data. All site activities are recorded in the logbook to allow review of activities which may affect data quality.

Site logbooks used to record daily activities at field sites including:

- method changes

- changes in calibration standards

- instrument failures and corrective actions

- site visits for audits

- electronic visits via remote access

- changes in computer configurations

- disk and file maintenance and all repair activities

In short, anything that occurs at the site may effect data validation and must be recorded in the logbook. The electronic logbook is archived on a nightly basis to insure integrity and allow data validators immediate access to important information regarding site specific activities which could affect data acquisition.

Archiving

Additional software, Merlin MicroScience Mmove, is provided to automatically compress and archive the data files generated each day. EZChrom initiates this activity nightly through the method file. Utilizing the date code in the file names, it compresses each day’s data files into a “single” compressed file with a unique site and date code name in a archive (*.zip) format. The method files and electronic logbooks for the site are also archived with the data. Through automating daily file maintenance we free up operator time to evaluate system performance and for data validation and reduce potential data losses from data handling and allow for automated file retrieval.

For users who have multiple systems data is archived each hour into a compressed file that can be accessed anytime. Orsat can provide additional configurations that will allow hourly transfer of data from multiple sites to a main host.

Remote Access

Remote control is possible for real-time inspection of the gas chromatographic data system via broadband connections. The daily compressed files can be automatically transferred to a remote computer without operator intervention each day or data files can be transferred hourly to a local host for immediate review or display.

Standard Operating Procedures

These documents are designed to aid the new user through a number of the standard daily operations they will be expected to accomplish at the site. Appendices contain a number of documents and details about all subsystems. Several common trouble shooting problems with their resolutions are included for reference.

Merlin AutoGC Xplorer (MAX) - Cloud-Based Data Management, Review, & Validation

EZChrom methods can be configured to output text files, which can be imported to many database formats. Orsat can provide cloud services, which allow the operators or managers to view an entire day’s data in tabular format using these text files. Users can poll their site once each day and collect the archived data which can then be uploaded into MAX via our secure internet site. MAX generates a daily QuickLook which not only shows the data collected but also calculates recoveries for check standards. MAX allows the generation of control charts of check standard recoveries and blanks over days, months or even years. This allows operators to catch system problems quickly, which might impact data, validation and greatly reduces the need for reprocessing of data.

Installation & Configuration

Orsat can install and configure your entire Markes-Agilent System from its manufacturer packaging. The entire process takes only 3–5 days with all the necessary gases and power requirements available. We recommend each site have an internet connection for remote access and data transfer. In addition, based on our experience with the power requirements of the system, Orsat recommends at least two separate 30 amp circuits be available for the gas chromatograph and thermal desorber. Separate 20 amp circuits should be provided for all ancillary equipment. Air conditioning and other heavy equipment should be well grounded and isolated from the system to reduce line noise, which can adversely affect the electrometer signals. Other recommendations can be found in the Orsat Site Implementation Recommendations for Markes/Agilent Systems.

Orsat offers additional Field Qualification for verification of system performance. This includes calibration and operation of up to one week to prove performance to specifications. See Preliminary Field Qualification data sheet for details on performance specification. Field Qualification is subject to availability of appropriate standards.

Custom installation and configuration provides each field site with a complete monitoring system, which can be configured and tested as a complete system. Software from several sources and hardware from multiple vendors can all be integrated into an effective system from the initial installation. Miscellaneous site-specific problems can be effectively managed from the onset providing a problem free monitoring site.

Installation and setup takes only 3 to 5 days once all the necessary gases and power services are available. Each site will need broadband service if remote access and data transfer are required, as well as climate control to prevent overheating of the hardware. Additonal information about site needs can be found in the Orsat Site Implementation Recommendations for Markes/Agilent Systems.

It all begins with the...

Preliminary Field Qualification

Acceptable system performance will be demonstrated by collecting measurement data over a continuous 7-day, demonstration period and verifying that all quality indicators are within the data quality objectives.

Orsat will qualify each system for detection limits, separation efficiency, method optimization as well as response factors and humidified blank criteria. Guidelines used for this qualification are accepted by U.S. EPA standards and are provided in our Quality Assurance Plan (QAP). A written certification is provided with each system for future reference that outlines all standards used, operational parameters, and retention time road maps.

Orsat can provide daily standards to be used with the blending system, which are certified and will last the duration of the operating season. Daily standards contain certified concentrations of propane and benzene for recovery calculations and up to 12 additional constituents used as reference peaks in the processing methods for the system. Additional standards and audit samples should be supplied by the customer at the time of installation to be incorporated into the certification document.

System qualification offers a comprehensive evaluation of the monitoring system from the outset of its deployment in a field setting. This data provides operators with detailed data by which they can evaluate the system’s subsequent performance. It also provides a standard, which can be used in the event of a failure to assist operators and maintenance personnel in their efforts to return the system to operation.

- Establish acceptable multipoint (3-point) calibration using the gas blender and a 14-component standard at 1 ppmv for each component.

- Calibration for components eluting on the PLOT column (C2 – C6) will use the average response factor for propane as ppb carbon and the calibration may not exceed 10% relative standard deviation.

- Calibration for components eluting on the boiling point (BP) column will use the average response factor for benzene as ppb carbon and the calibration may not exceed 10% relative standard deviation.

- Initialize collection of data for 7-day demonstration period.

- Analyze daily 14-component calibration verification samples (CVS) and daily field blanks during the demonstration period.

- Analyze one duplicate CVS immediately following one daily CVS (precision check).

- Analyze a second source laboratory control sample (LCS) containing the same 14 target compounds as the CVS and diluted to nominally 5 ppbV in a summa canister which is also used to verify the blended calibration check, calibration curve and calibration standard.

- Verify that all components are being correctly identified using US EPA 56-component retention time standard.

Field Certification Report

With each field qualification, a certification report is issued that contains the following information for future reference:

- Multipoint calibration data sheet

- CVS Recovery report for sampling period

- Precision report for duplicate runs and for daily check standards

- Field blank report for sampling period

- LCS recovery report

- Data completeness calculation

- Chromatograms of retention time standard, ambient air and blanks

Data Quality Objectives:

Multipoint Calibration:

RSD < 10% for average response factor over calibration range.

CVS Recovery:

Benzene and Propane within 75–125%; all other CVS compounds within 55 – 145%.

Precision:

Relative percent difference (RPD) for benzene and propane < 20%

LCS Recovery:

Recovery of benzene and propane within 70 – 130%; all other CVS compounds detected.

Daily Field Blank:

Total non-methane hydrocarbons < 20 ppbC, and individual target compounds < 2.0 ppbC.

Completeness (Data Capture):

For the 7-day demonstration period must be greater than or equal to 90% valid hours of operation.

(Completeness is calculated as the number of hours of valid data, expressed as a percentage of the total number of hours of operation, excluding hours during which a calibration or quality control test is being conducted. Down time for maintenance is not excluded.)

Have a look inside…

Chris Owen, a technical specialist in the TCEQ’s Air Quality division shows us around an AutoGC

Tour the TCEQ’s Auto-GC Monitor in Floresville, Texas

In this video, Chris Owen, a technical specialist in the TCEQ’s Air Quality division shows us around an AutoGC site deployed and maintained by Orsat in the Eagle Ford Shale formation of central Texas.

We’re at the Floresville air monitoring site today where we have an automated gas chromatograph, a NOx instrument to measure oxides and nitrogen, and meteorological measurements. Our AutoGC system is used throughout…

Orsat

Orsat